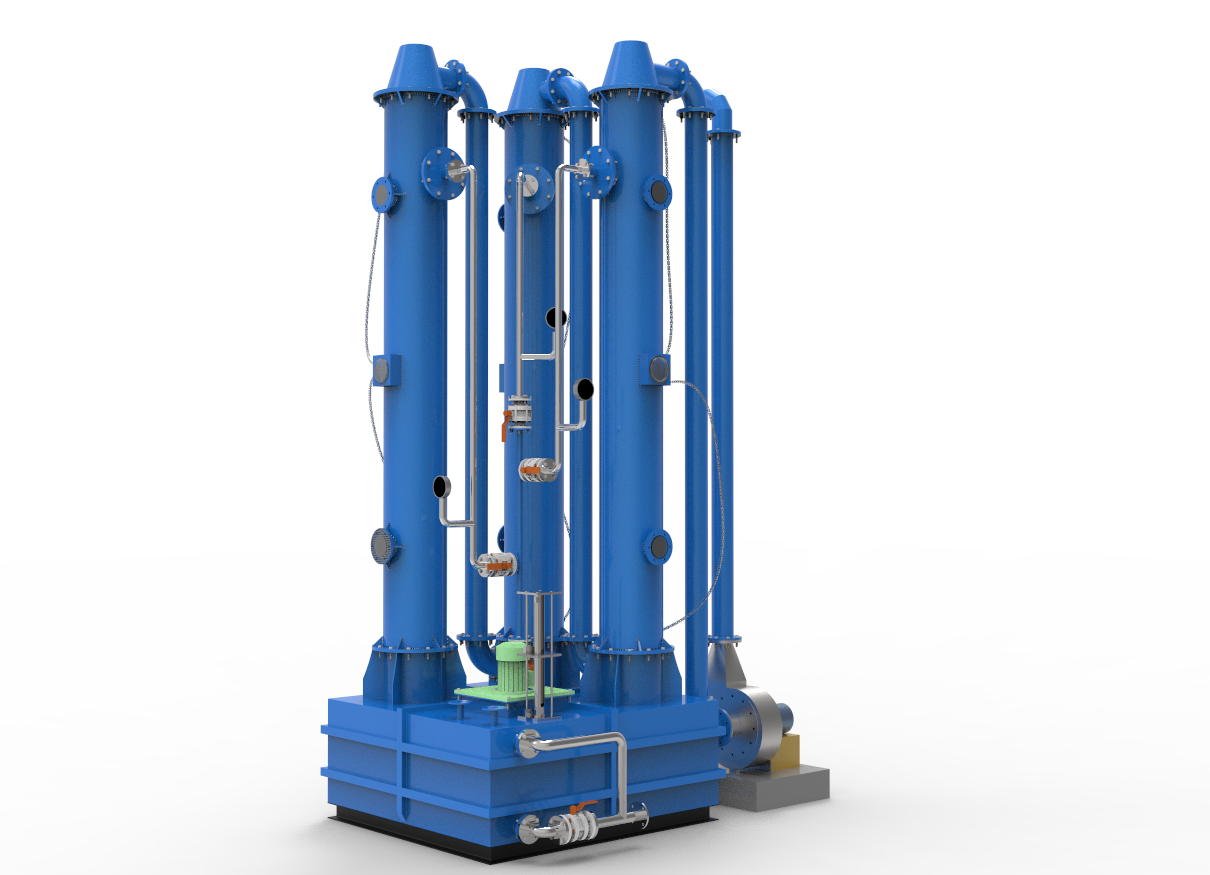

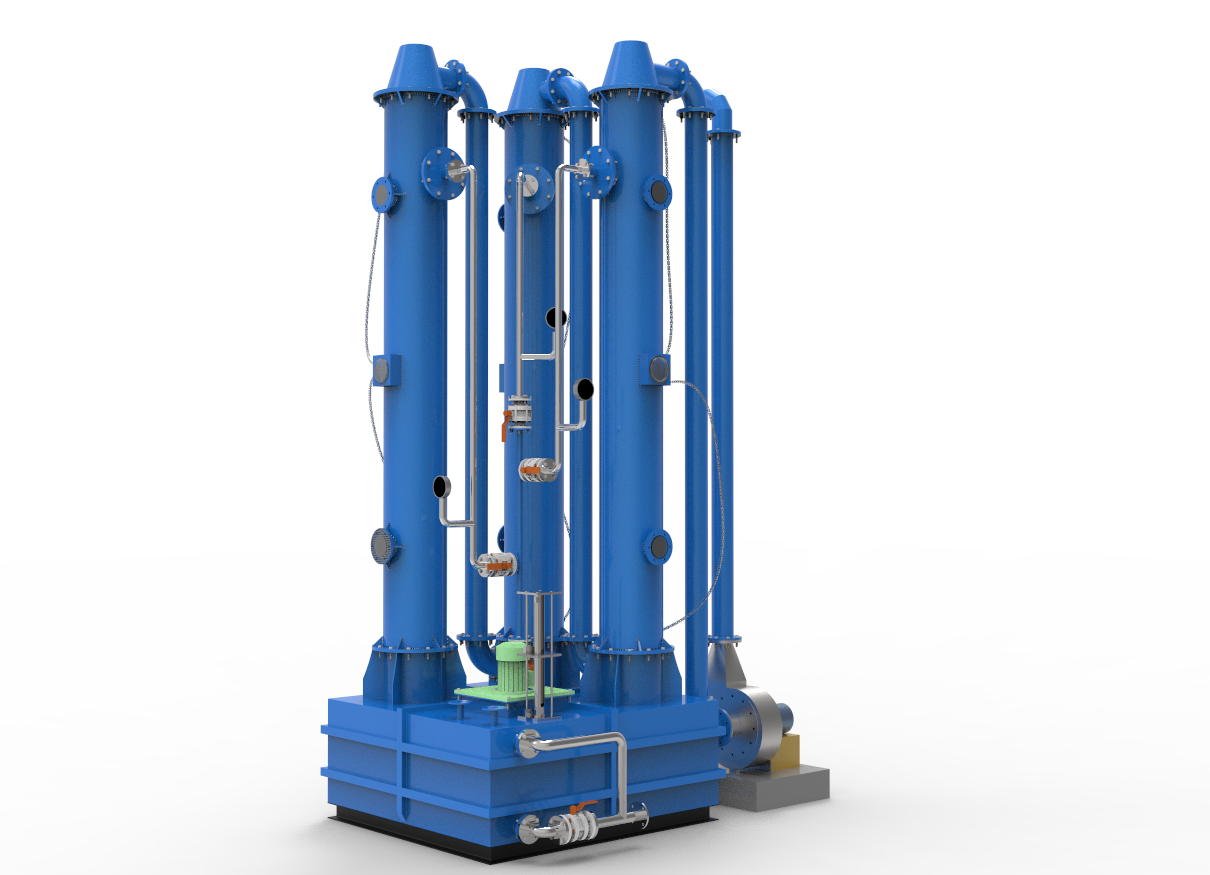

Ethylene Oxide Scrubber

Ethylene Oxide Scrubber

- Hospital equipment sterilization facilities are among those sources that use ethylene oxide (EtO) for sterilization which is recognized as the best practice by the medical industry.

- With no suitable alternative available at this time, controlling exposure through air pollution control is necessary as the U.S. EPA has identified ethylene oxide as a hazardous air pollutants (HAPs).

- Both EO (Ethylene Oxide) and PO (Propylene Oxide) are characterized by relatively high vapor pressures in aqueous solution. Consequently, unless the EO and PO are transformed into other substances in solution, the scrubbing liquid stream cannot practically be recirculated within the scrubbing system and still result in effective removal.

- The alternative, using once-through water for scrubbing, is not generally practical due to the cost of the water and its treatment. However EO and PO can be transformed to their respective glycols when hydrolyzed but the hydrolysis reaction is very slow.

- The alternative, using once-through water for scrubbing, is not generally practical due to the cost of the water and its treatment. However EO and PO can be transformed to their respective glycols when hydrolyzed but the hydrolysis reaction is very slow.

Exposure limit of Ethylene oxide

Employee exposure is limited to one part EtO per million parts of air (1 ppm) measured as an 8-hour time-weighted average (TWA).

Exposure should not exceed the short-term excursion limit of 5 ppm EtO averaged over any 15-minute sampling period.

Working principle

⦁ A counter current packed tower is used to absorb the EO or PO in aqueous solution. The liquid exiting the packed tower drains to the “Reactor Tank” which is designed with sufficient residence time and with certain proprietary internals such that the liquid discharging from the top of the “Reactor Tank” contains only minute amounts of EO or PO since conversion to the glycols has taken place.

⦁ The liquid stream then flows over to the “Solution Feed Tank” where the flexibility of operating with varying liquid levels allows for the “swell” of volume as glycol is generated, the discharging of “spent solution” when the tank’s capacity has been reached, and the addition of fresh sulfuric acid and water to replace that lost when the “spent solution” is discharged.

⦁ As a result this system can operate continuously, if necessary, as discharging of “spent solution” and make-up of fresh solution is accomplished automatically.

⦁ EtO is extremely water soluble, so vent gas is typically fed to a scrubber column filled with random packing and the EtO is absorbed by an aqueous stream running countercurrent to the vent gas to complete the hydrolysis of the EtO.

⦁ Once the concentration of ethylene glycol reaches a predetermined weight percentage, the efficiency of the scrubber declines requiring process downtime as the scrubber liquid needs to be replaced and properly disposed of leading to additional ongoing operating costs.

⦁ In a closed system the air that contains ethylene is sucked from the lower ducts and passed through the chemical filters where it gets neutralized and the clean air is released outside. This chemical filter is a metal silicate that is soaked with Potassium Permanganate KMnO4, which is an oxidizer that release water and CO2 while reacting with Ethylene.

Features

⦁ Can handle air flow rate from 100 to 30,000 CFM

⦁ Removal method is Absorption / Chemisorption

⦁ Material of Construction: PP, FRP, PP+FRP, MS+FRP, SS 304, SS 316

⦁ High efficiency Tellerette® Tower Packing removes soluble/reactive gases

⦁ Lower shell serves as integral sump for recycle of liquid

⦁ Spray nozzles accessible from top of unit

⦁ Entrainment separators prevent liquid carryover

⦁ Efficiency up to 99 %

Advantages

⦁ No Hazardous By Products

⦁ All Stainless Steel and FRP construction

⦁ No Rusting

⦁ No High Temperature Duct

⦁ Room Temperature Operation

⦁ Minimum Energy Costs

⦁ Low Maintenance and Monitoring

Advantages

⦁ Chemical Reactors of ETO Manufacturing Plant

⦁ ETO Bottling Plat

⦁ Medical Disposable & Surgical Industry

⦁ Spice & Food Processing

⦁ Storage Tank Venting

⦁ Contract Sterilization Facilities

⦁ Pharmaceutical Processes

Frequently Asked Questions

An ethylene oxide scrubber is a pollution control device used to remove ethylene oxide (EO) gas from industrial exhaust streams. These scrubbers prevent the release of this highly toxic and carcinogenic gas into the atmosphere, protecting workers and the environment.

Ethylene oxide scrubbers work by using a scrubbing solution (usually water or an alkaline solution) to absorb or neutralize ethylene oxide gas. The exhaust gas is passed through the scrubbing medium where EO dissolves or reacts with the solution, thereby removing it from the air before it is released.

Ethylene oxide scrubbers are commonly used in:

- Chemical Manufacturing (production of ethylene oxide and related products)

- Pharmaceuticals (sterilizing medical equipment using ethylene oxide)

- Sterilization Facilities (controlling emissions from EO-based sterilization processes)

- Fumigation (in processes using ethylene oxide as a fumigant)

- Ethylene oxide is a colorless, flammable gas widely used in the chemical industry and sterilization processes. It is harmful because it is toxic, carcinogenic, and can cause serious health issues, including respiratory problems, nerve damage, and an increased risk of cancer.

- Health and Safety: Protects workers from harmful exposure to ethylene oxide gas.

- Environmental Compliance: Ensures compliance with air quality regulations by capturing ethylene oxide emissions.

- High Efficiency: Scrubbers can remove up to 95-99% of ethylene oxide from the exhaust stream.

- Customizable: Scrubber systems can be tailored to the specific needs of different industries and emission volumes.

- Maintenance: Regular maintenance and cleaning are required to keep the scrubber functioning efficiently.

- Waste Disposal: The used scrubbing solution, which contains ethylene oxide, must be treated and disposed of according to environmental regulations.

- Cost: The installation, operation, and maintenance of ethylene oxide scrubbers can be costly.