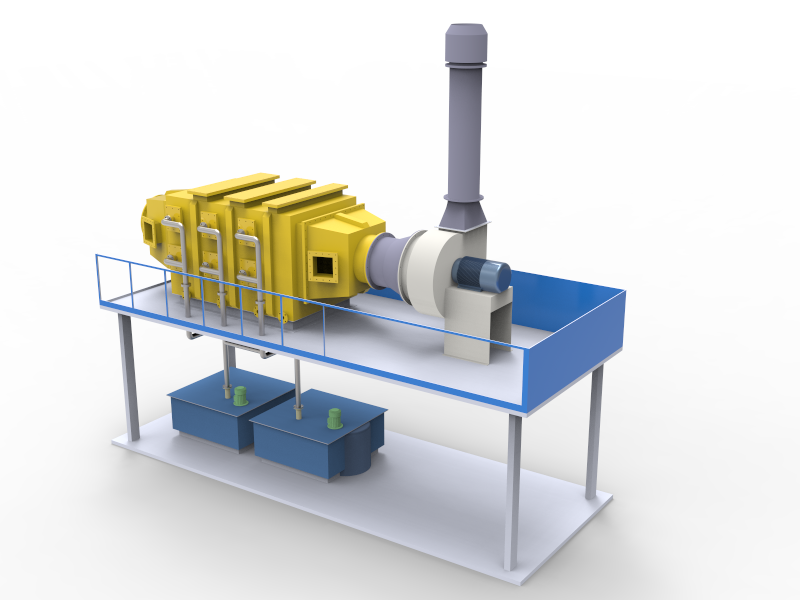

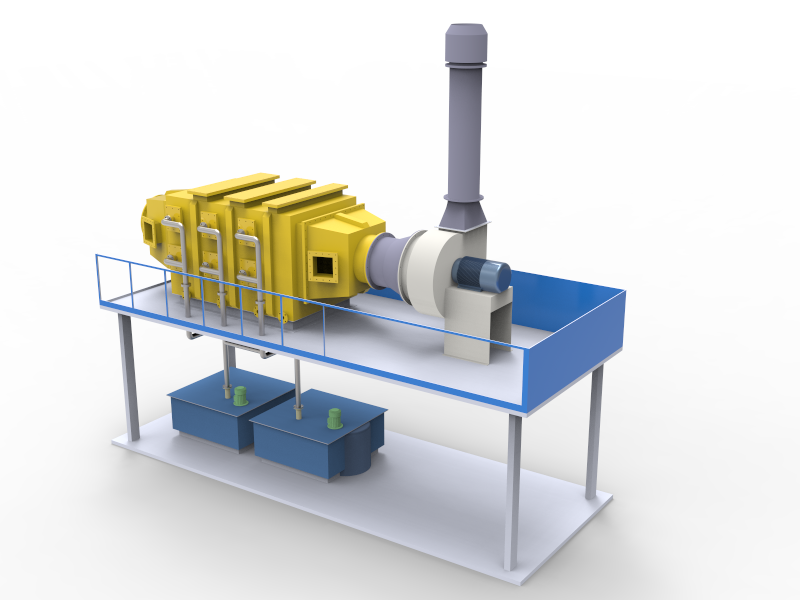

Chromic acid scrubber

Chromic acid scrubber

Chromic acid scrubber is also called as Hard chrome plating scrubber. Drizgas Tech’s Mist Eliminator Systems featuring its composite mesh-pad designs have been used. We are one of the leading manufacturer of chromic acid scrubber in India.

Chromium

Chromium occurs in the environment primarily in two valence states, trivalent chromium (Cr III) and hexavalent chromium (Cr VI). Exposure may occur from natural or industrial sources of chromium. Chromium VI Chromium (VI) is much more toxic than chromium (III), for both acute and chronic exposures. The respiratory tract is also the major target organ for chromium (III) toxicity, similar to chromium (VI). Chromium (III) is an essential element in humans.

Human studies have clearly established that inhaled chromium (VI) is a human carcinogen, resulting in an increased risk of lung cancer.

The metal chromium is used mainly for making steel and other alloys. (1) Chromium compounds, in either the chromium (III) or chromium (VI) forms, are used for chrome plating, the manufacture of dyes and pigments, leather and wood preservation, and treatment of cooling tower water. Smaller amounts are used in drilling muds, textiles, and toner for copying machines.

Chrome plating

In hard and decorative plating, the object to be plated is placed in a bath with a chromic acid solution. The object is then connected at the negative electrode of an electrolytic cell. When a voltage is placed across the cell, chromium is deposited on the object.

However, as a side reaction, water in the plating solution decomposes to oxygen and hydrogen. As those gases rise to the surface, the gas bubbles burst creating chromic acid mist droplets. These droplets are collected in hoods and exhausted to control devices like scrubbers. The exhaust airflow is then emitted into the atmosphere.

Chrome plating involves the electrolytic deposition of chromium onto metal components. Plating baths of chromic acid are most widely used in the industry. These baths produce very fine mists of chromic acid which must be controlled. Airborne emissions of chromic acid are facing increasingly stringent pollution abatement requirements.

In almost all applications where high efficiency control of hexavalent chromium is required for regulatory compliance.

Exposure limit

The following exposure limits are for Chromic Acid (measured as Chromium VI):

OSHA: The legal airborne permissible exposure limit (PEL) is 0.1 mg/m3, not to be exceeded at any time.

NIOSH: The recommended airborne exposure limit is 0.001 mg/m3, which should not be exceeded at any time.

Chrome scrubber design

We are using the uniquely interlaced monofilament structure. Each style of coarseness of this structure has its own performance characteristics – removal efficiency, liquid handling capacity, pluggage resistance, pressure drop, etc.

Mesh pad designs can run from simple elements comprised of one style, to more complex pads comprised of several styles-composite pads. Composite pads are important in chrome scrubbing because high removal efficiency, high liquid handling and reduced maintenance are critical. The tough emission standards set down by the pollution control board can be met. This has been demonstrated by various technologies including units utilizing the uniquely interlaced monofilament structure.

Principle of operation

- Drizgas Tech’s Mist Eliminator Systems featuring its composite mesh-pad designs have been used.

- Our designs achieve emissions below 0.001 mg/m3.

- Composite mesh-pad technology has been determined to be the most effective control technique and represents the most reasonable approach to controlling emissions of chromic acid from all hard chrome plating operations. Further, our systems provide the lowest economic impact to the customer when compared to other competing technologies.

- The designs typically incorporate several stages of our composite mesh-pads. Each stage provides progressively higher efficiency. The initial stages provide coarse separation and the bulk removal of the chromic acid mists.

- Our intermediate stage provides greater than 99% collection of all droplets down to 1 micron in size. This level of performance is required to meet the most stringent emission limits. However, the stage is also protected from fouling and maintenance due to the stage-wise separation of the droplets.

- Our composite mesh-pads are provided in removable cassettes which allow for ease of cleaning and maintenance, when necessary. This feature allows the mesh Pads to be cleaned and re-used for many years, providing cost-effective solutions for your plating emission needs.

We are happy to provide the best, most cost-effective designs to meet your requirements. Drizgas Tech is one of the leading manufacturer of hard chrome plating scrubber in India. Contact us with your process information so we can begin discussing the type of new equipment that best fits your situation.

Mechanism

- The Fume Scrubber usually works in conjunction with either the exhaust of an etching machine or chrome plating system. The fumes of these acids are simply suspended droplets of contaminated vapor and are re-solubilized when passed through a liquid rich environment.

- The exhaust fumes are either blown from the etcher or plater at the bottom end of the scrubber, or they may be sucked up by a blower fitted at the top end of the scrubber. As air is introduced into the bottom of the scrubber, it passes up through and around many specially shaped plastic pieces so that the air cannot go in a straight line, but must contact a wet surface.

- The water within the scrubber recirculates because the pump sprays a fine mist of liquid at the top of the scrubber. This mist permeates down (as the exhaust air goes up) and coats the many particles of plastic before it returns to the sump at the bottom.

- The water within the scrubber recirculates because the pump sprays a fine mist of liquid at the top of the scrubber. This mist permeates down (as the exhaust air goes up) and coats the many particles of plastic before it returns to the sump at the bottom.

- Spray pressure can be regulated for the optimum situation. Additionally, there is a mist eliminator at the top of the scrubber which prevents water droplets from going out the exhaust.

- The Fume Scrubber is 99.9% efficient in removing the gaseous contaminates in either a ferric chloride or chromic acid environment. Air quality requirements of certain municipalities make the Exhaust Fume Scrubber a requirement so as to pretreat the air prior to discharge.

Specification

nism

- Air flow rate from 50 to 70000 CFM

- Material of construction: PP, PP+FRP, MS, SS 304, SS 316

- Scrubbing efficiency up to 99.9 %

- Spray nozzles accessible from top of unit

- Entrainment separators prevent liquid carryover

- Power supply: 3 Phase

- Customization: Yes, customization available suiting your needs

Frequently Asked Questions

A chromic acid scrubber is a pollution control device designed to capture and neutralize chromic acid mist and vapors from industrial exhaust streams, ensuring compliance with air quality standards and protecting woers and the environment from the toxic effects of hexavalent chromium.

Chromic acid scrubbers use liquid scrubbing solutions, typically water mixed with neutralizing agents, to absorb and neutralize chromic acid mist and vapors. In some designs, the mist is first captured by demisters or mesh pads before the exhaust stream passes through the scrubbing medium for final treatment.

Chromic acid mist refers to tiny droplets or aerosols of chromic acid (H₂CrO₄) that are released during industrial processes such as plating, anodizing, or etching. This mist is toxic and carcinogenic, posing significant health risks to workers and requiring controlled ventilation and treatment.

- Wet Scrubbers: Utilize a liquid scrubbing solution to neutralize mist and fumes.

- Packed Bed Scrubbers: Use packing material to increase contact between the scrubbing solution and exhaust gases for better absorption.

- Venturi Scrubbers: A high-velocity scrubber that uses liquid to capture and neutralize mist efficiently.

- Health & Safety: Reduces worker exposure to toxic chromic acid mist.

- Environmental Compliance: Ensures that emissions meet regulatory standards for air quality.

- Efficiency: Effectively captures and neutralizes harmful chromic acid vapors.

- Customizable: Designed to suit specific processes and gas flow rates in different industries.

- Maintenance: Regular cleaning is necessary to prevent scaling, corrosion, and system fouling.

- Waste Disposal: The neutralized chromic acid waste must be managed carefully to prevent environmental contamination.

- Initial Cost: Chromic acid scrubbers can be costly to install and maintain, especially in complex operations.